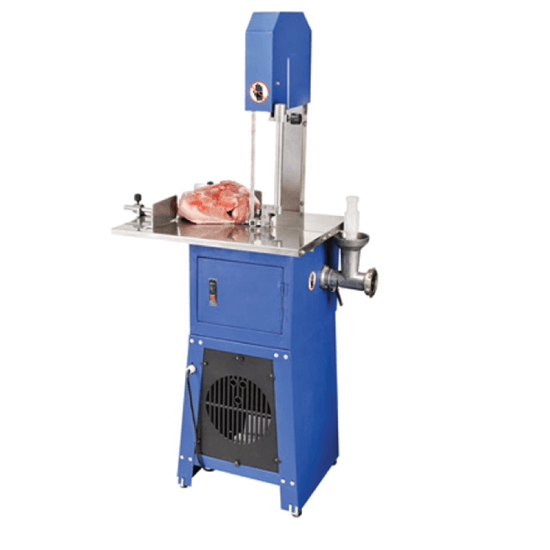

Meat bone cutting machine is a high-performance bone, meat cutting machine. It is used to slice meat, bone, frozen meat, poultry and fish in customized size within a short time with efficiency.

Our Clients

H#199 (1st Floor), R#01, New DOHS Mohakhali, Dhaka-1206, Bangladesh

Smooth Cutting Operation

Commercial Bone Saw Machine cut bones and meat smoothly with suitable shapes. You can customize bone and meat cutting size according to your needs. Its smooth operation makes you more comfortable and productive. This product facilitates you to change the thickness of meat and frozen fish along with the smooth process

Strong Body Material

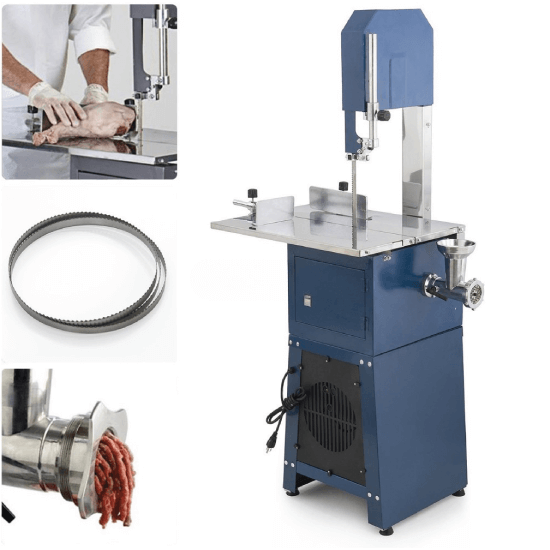

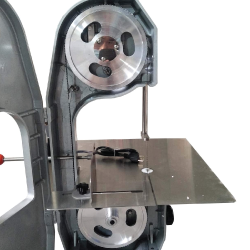

Butcher bone saw body is made of heavy-duty steel. Body equipment includes work bench, band saw protector, meat pusher, handle, non-slip base, Cover, cover lock, switch, and blades. All these parts are manufactured from aluminum. The parts those are in touch with foods are made of high-quality stainless steel. This combination of aluminum and stainless steel makes this bone saw machine stronger.

Safety Feature

Commercial Butcher bone saw machine has cover lock that saves the machine and blade operating system. You can open the cover lock whenever you need. There is a meat pusher that ensures safety of your hands from the sharp blades. It also helps you to cut the bones in right way. Band saw protector protects the blades as well as your hands when you cut small size of bones, meat, or frozen fish. Moreover, non-slip base enables you to move the machine easily. At the same time, it defends unnecessary movement of the Butcher bone saw.

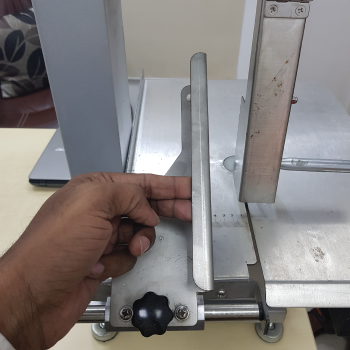

Adjustable Fence

Meat and Fish Cutting Machine has unique type of fence. This fence is adoptable to different size of meat, and bones. Operator can easily change the fence distance from the blade. By doing this, you can change the thickness of meat slice and enjoy customized meat size with efficiency. There is a meat pusher that keep your hands away from the saw.

Hygienic/Healthy Operation

Meat Cutting Machine provides a hygienic operation when it slices meat, bone, fish, and poultry. Because, the whole body is made of aluminum but the parts – those are in touch with food are made of high-quality stainless steel. The work table is also stainless steel sprayed. This stainless steel protects food from any contamination and keeps food safe and hygienic. This machine is manufactured considering strict food safety standards.

Easy to use/Self-operated

Commercial Bone Saw Machine is very easy to use. You just need to open the cover first and then unlock the 2 clips inside the unit. After checking, you need to plug in the machine to power. After that, place your meat or bones on the work bench and adjust to your desired thickness. Then you need to switch “On” the unit and start cutting meat, bones, frozen fish etc. After slicing meat and bones, turn “Off” the machine and unplug it from power. Anyone can operate this bone cutting machine very easily.

Best Materials

Electric meat cutter saw machine is manufactured with high quality materials. It has strong aluminum alloy body along with sharp and durable blades. The surface of work table is stainless steel sprayed to protect foods from any contamination. All surface materials are proven to protect environmental damage. Covers, doors, and blades are made of aluminum and stainless steel.

Blade Size

Different size of blade is available for home and commercial use of Bone Saw Machine. The saw blade measures 48 inches, 64 inches, 82 inches, and 89 inches. These blades are imported from China, Italy, Korea, and Sweden. It is sharp and sturdy, and the saw blade tension organism can adjust the blade to the perfect style. So, you can set them according to your necessity.

High Productivity and Low Energy Consumption

Electric Bone Saw Machine can cut huge bones, and meat in a very short time. But it consumes minimum energy. As a result, commercials can conduct high level of productivity with low cost. If you use the product eight hours a day, you will be charged only 3000/- BDT at the end of the month.

Parts Availability

The body parts of the fish cutting machine are available. Primarily, Commercial Bone Saw Machine needs different size of blades based on your operation. Blades of meat saw machine are available in local and global market. Domestic market import blades and other parts of the product mostly from China, Italy, Korea, and Sweden. Other parts including work bench, band saw protector, meat pusher, handle, non-slip bases are available in the market.

Area of Use

Bone saw machines are perfect for cutting meat, bones, poultry, and fish. These machines used in the hotels, restaurants, food processing plants, and butcheries vastly. More importantly, you can use this product for both purpose; commercial and family use.

Easy Cleaning

This saw machine is very easy to clean. You can clean the surface by soft cloths and sponge to remove meat powder from the work table. You can use detergent and water to wash the surface of table. Similarly, you can clean the inside of the machine by opening the cover hatch. Use sponge to remove meat crumbs from the inside of the unit. You can use water spray and detergent to wash the oil of meat on the blade.

Warranty

Electric bone and meat slicing machine provide 1-year service warranty. You will get any kind of services free for one year. After expiring the service warranty, you have to pay for services. If you need any kinds of equipment, you have to pay for that products.

Product Features & Benefits

- Stainless Steel Body

- Emergency Switch

- Adjustable Thickness

- Hand Push Shank

- Imported Blade

- Different Sizes

- Copper Motor

- Standard Warranty

Product Specification

Model | J210S |

Saw blade model | F210A |

Power | 1100w |

Blade Size | 1650mm (64") |

Voltage | 220v/50Hz |

Weight | 44kg |

Size | 55*46*95cm |

Frequently asked questions and Answers

Meat bone saw machine has a very simple work process. the sharp blade of Meat bone saw machine starts to revolve when the unit is switched on. Then it can cut all meat, bone, frozen fishes, and poultry. An operator operates this with meat pusher. Total process occurs on the work bench. There is also function of changing the thickness of meat slice.

The bone saw machine could be different based the shape and features. Largely, there are two types of meat saw machine. One is manufactured for commercial use. Another is for home. Home bone saw machine is comparably small than commercial one.

This product is made of high-quality aluminum and stainless steel. Main body and the machine are from aluminum. On the other hand, the parts in touch with food are made of high-quality stainless steel. This combination made the product strong and long durable.

Commercial butcher bone saw is a multi-functional product. It cuts not only bones but also meat, fish, frozen fish and meat, and so on. We face problem to slice meats, bone, frozen fishes in daily life. If you want to cut these foods easily and save time, you can use butcher bone saw. Specially, hotels, restaurants, food processing plants, and butcheries use this product to cut huge quantity of meats, fishes, and bones.

Imagine, you have to process 1 mound meat for you client, but you have only one hour to deliver meat. How you prepare that huge meat within short time. It is tough to cut them manually by one or two employees. Then, what will be the best solution? If you are facing these hassles to process meat, bones and frozen fish, heavy duty bone saw machine is recommended for you.

Commercial Butcher Bone Saw Machine Will –

Decrease meat waste.

Decrease your hassles.

Save time.

Make you meat slice polished and smooth.

Satisfy your customer with customized number pieces.

Use of Electric Bone Saw Machine is simple. You can use these steps to use this product correctly.

Step-1: Wear protective gloves for safety before using Electric meat Saw Machine.

Step-2: Open the cover and unlock the two clips in front of the unit.

Step-3: Adjust the gear to fasten the pulley.

Step-4: Check the stability of the elevator by rotating the gear clockwise.

Step-5: Set the guide according to your desired thickness.

Step-6: Plug the unit.

Step 7: Prepare the bone, meat, or frozen fish. Then place it on the work bench.

Step 8: Switch the unit.

Step 9: Move the bone to the blade.

Step 10: Turn off the machine after use and clean it properly.

When replacing the saw blade, spin the handle anticlockwise to release the blade. Please pay close attention to the guidelines when installing the replacement blade. Otherwise, the saw blade will get detached from the machine. Please ensure that the saw blade and slicer are properly placed between the top wheel and bottom pulley and that they pass through the guide groove. The tension knob should be adjusted until the loosened wheel makes a slicing sound. This sound indicates that the blade is properly tensioned. Make sure you use the correct saw blade for the sort of food you're cutting.

Body materials of Electric meat Saw Machine are aluminum and stainless steel. Blades are also stainless steel sprayed.

The saw blade measures 48 inches, 64 inches, 82 inches, and 89 inches. These blades are imported from China, Italy, Korea, and Sweden. It is sharp and sturdy, and the saw blade tension organism can adjust the blade to the perfect style. So, you can set them according to your necessity.

This product consumes low energy and produce high productivity. If you use the meat cutter machine 8 hours a day, it will cost around 3000 Taka for one month.

Cleaning bone saw machine is easy. You can follow some simple steps to clean your fish saw machine.

Step 1: Open the cover.

Step 2: Regulate the pulley screws to loosen the blade.

Step 3: Remove the blade, upper gear, screws, and other small parts.

Step 4: Remove meat powder.

Step 5: Wash the inside of the unit with sponge and water spray. You can use detergent to wash blade.

Step 6: Wipe all parts with cloths. Make sure all parts are dry before reset the equipment.

Step 7: Reset all parts and close the cover.

Similarly, you can clean and wash the work bench and surface of the bone saw machine.

Do’s: Do this.

Wear sate gloves before using the saw machine.

When remounting the saw blade, ensure that the teeth are pointed downward.

The correct side of the saw blade should be in the middle of the meat scraper.

Make sure the teeth of the blade should be sitting out on the edge of the pulley.

Rotate the top pulley after attaching the blade.

Turn off the unit after use.

Don’ts: Don’t do this.

Never attempt to clean bone saw while bone saw is in operation.

Do not put components in the dishwasher or immerse base in water.

Do not hose down, pressure wash, or pour water on bone saw.

Never use a scrubber pad, steel wool, or abrasive material to clean bone saw.

Never use abrasive products, chlorate substances, wire wools, brushes of any type, scrapers, etc. to clean the machine.

After buying this product, you will get one-year service warranty. After expiring the service warranty, you have to pay for services. If you need any kinds of equipment, you have to pay for that products.

Having stock or not and comparing to the world market, this products price can be up & down. But right now, Commercial Bone Saw Machine Starting Cost is 85,000 Taka Price in Bangladesh.de If you want to buy, the price can be up & down depending on the feature, specification and other customization.

Product Reviews

Read all reviewsDr Jahangir Alam

From on 15th Oct, 0018Estaq Fardous Bhuiyan

From Dutch Dairy Ltd on 12th Aug, 2021Rana

From Mugda on 28th Nov, 2017Maulana Monir Hossain

From Mohammadia Kancha Bazar on 24th Sep, 2018Dr. Jahangir Alam

From BADC on 15th Oct, 2018Submit your review

Your email address will not be published. Required fields are markedAdd Images & Videos to your review

Allowed file types: jpg, gif, png,mp4,avi max total size of files: 100MB, max number of files: 8!